“You can’t manage what you don’t measure.” You’ve probably heard this phrase before; it has a lot of merit. How can you expect to make the best decisions with little to no information? Data doesn’t just tell a story, if used correctly, it’s a predictor of what’s to come. In the world of reliability, history provides insight of what may be to come, otherwise known as failure forecasting, which uses the information to mitigate unforeseen disasters. That is the power data. As we all know history loves to repeat itself. Knowing how to be prepared for these challenges touches into the realm of reliability, a prerequisite of obtaining robust solutions. Data begets knowledge, and knowledge is power.

Compressed air systems, are vital for manufacturing, an essential utility like electricity. Unfortunately, they aren’t always treated as such. If you want to “set it and forget it” and at the same time relieve yourself, team, and the company of the daily burden then it makes complete sense to do so with automation. Utilize what technology has to offer and augment your compressed air system so that you can be ready when issues arise. “An ounce of prevention is worth a pound of cure.”

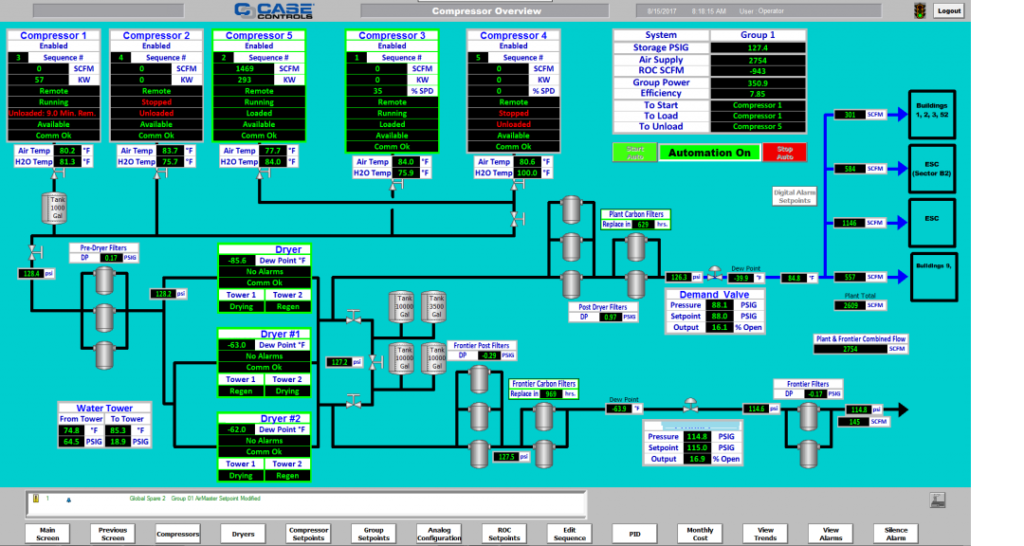

Data is great, but it needs to be exercised and represented in a manner that is easy to use, understand, and access. It must exist in real-time and have the ability to send alerts, alarms, and notifications to the right authorities when certain conditions arise so that there is time to react. Data accessible via a plant network, DCS/SCADA, the cloud, or a hybrid system means that no matter where you are you have the ability to analyze the information quickly and easily understand what is going on. The quicker you can gain access to the information, the faster and smarter decisions you can make that ultimately save time, money, and stress.

KPIs for the win

Data needs to be reviewable, a history of cause and effect, so that it is possible to measure progress and continually make improvements. These metrics are very important to justifying a plan of action, developing budgets, and reporting. One of these reporting metrics are KPIs or key performance indicators. KPIs are typically ratios of different values that are used to easily understand the performance of a particular process. CFM/kW is one example that illustrates how much compressed air is generated per input power. This creates a benchmark for a measure of efficiency on an individual compressor and the system as a whole. There are numerous types of KPIs that can be developed and employed to easily keep watch over a system without having to run daily tests and calculations. Advanced controls should allow KPIs to be entirely customizable, reflecting what is important to your plant and company.

If you need helping setting up the right data custom KPIs for your compressed air system, learn how Case Controls can help.